Sisitemu zo gukonjesha azote y'amazi zikoreshwa cyane mu nganda za semiconductor na chips, harimo n'uburyo bwo,

- Ikoranabuhanga rya Molecular Beam Epitaxy (MBE)

- Ikizamini cya chip nyuma yo gupima COB

Ibicuruzwa bifitanye isano

EPITAXY Y'UMURABWO WA MOLECULAR

Ikoranabuhanga rya Molecular Beam Epitaxy (MBE) ryakozwe mu myaka ya 1950 kugira ngo ritegure ibikoresho bya semiconductor thin film hakoreshejwe ikoranabuhanga rya vacuum evaporation. Hamwe n'iterambere ry'ikoranabuhanga rya vacuum cleaner riri hejuru cyane, ikoreshwa ry'ikoranabuhanga ryagiye rigera no mu rwego rwa siyansi ya semiconductor.

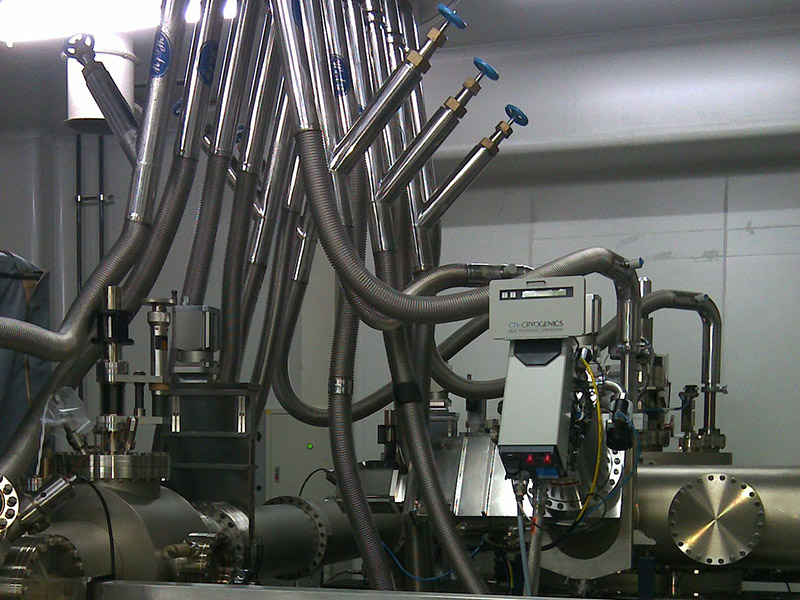

HL yabonye ko sisitemu yo gukonjesha azote y’amazi ya MBE ikenewe, ikora neza mu bijyanye n’ikoranabuhanga kugira ngo ikore neza sisitemu yihariye yo gukonjesha azote y’amazi ya MBE ku ikoranabuhanga rya MBE hamwe n’urutonde rwuzuye rw’imiyoboro ifunga ifu, yakoreshejwe mu bigo byinshi, za kaminuza n’ibigo by’ubushakashatsi.

Ibibazo bikunze kugaragara mu nganda za semiconductor na chip birimo,

- Umuvuduko wa azote y'amazi mu bikoresho bya Terminal (MBE). Irinde umuvuduko mwinshi uva ku bikoresho bya Terminal (MBE) byangiza.

- Uburyo bwinshi bwo kwinjira n'aho gusohokera amazi (Multiple Cryogenic Liquid Inlet)

- Ubushyuhe bwa azote y'amazi mu bikoresho bya Terminal

- Imyuka ihumanya ikirere ihagije

- (Kwikora) Guhindura imirongo mikuru n'ishami

- Guhindura umuvuduko (Kugabanya) no Guhagarara neza kwa VIP

- Gusukura umwanda ushobora kubaho n'ibisigazwa by'urubura mu kigega

- Igihe cyo Kuzuza Ibikoresho by'Amazi bya Terminal

- Gukonjesha umuyoboro mbere y'uko utangira

- Ubudahangarwa bw'amazi muri Sisitemu ya VIP

- Kugenzura ibura rya azote y'amazi mu gihe cy'igabanuka ry'imikorere ya sisitemu

Umuyoboro wa HL ukingira umuvuduko (VIP) wubatswe hakurikijwe kode ya ASME B31.3 Pressure Piping nk'ihame. Ubunararibonye mu by'ubwubatsi n'ubushobozi bwo kugenzura ubuziranenge kugira ngo harebwe imikorere myiza n'uburyo ikiguzi cy'uruganda rw'umukiriya gikoreshwa.

IBISUBIZO

HL Cryogenic Equipment itanga Sisitemu yo gufunga imiyoboro ikoresha umwuka kugira ngo yuzuze ibisabwa n'inganda zikora semiconductor na chips:

1. Sisitemu yo gucunga ubuziranenge: Kode y'imiyoboro y'umuvuduko ya ASME B31.3.

2. Imashini igabanya ibice yihariye ifite uburyo bwinshi bwo kwinjira n'aho gusohokera amazi (Multiple Cryogenic Liquid Inlet and Outlet) ifite ubushobozi bwo kugenzura imikorere yayo bwite, ihuye n'ibisabwa mu ibyuka bihumanya ikirere, azote y'amazi ishobora kongera gukoreshwa ndetse n'ubushyuhe bwa azote y'amazi.

3. Igishushanyo mbonera cy’imyotsi isohora umwuka gihagije kandi ku gihe gituma ibikoresho bya terminale bihora bikora neza mu gaciro k’umuvuduko wabigenewe.

4. Gaz-liquid Barrier ishyirwa mu muyoboro wa VI uhagaze ku mpera y'umuyoboro wa VI. Gaz-liquid Barrier ikoresha ihame ryo gufunga gaze kugira ngo ihagarike ubushyuhe kuva ku mpera y'umuyoboro wa VI kugera mu muyoboro wa VI, kandi igabanye neza igihombo cya azote y'amazi mu gihe cy'imikorere idakomeza kandi idahoraho ya sisitemu.

5. VI Imiyoboro igenzurwa na Valve Ikingira Uduce (VIV): Harimo Valve Ikingira Uduce (Pneumatic) Ikingira Uduce, Valve Ikingira Uduce, Valve Igenzura Uduce n'ibindi. Ubwoko butandukanye bwa VIV bushobora guhuzwa kugira ngo bugenzure VIP uko bikenewe. VIV ihuzwa na VIP isanzwe mu ruganda, nta gushyushya Uduce. Igice cyo gufunga cya VIV gishobora gusimburwa byoroshye. (HL yemera ikirango cya valve cryogenic cyagenwe n'abakiriya, hanyuma igakora valves zikingira uduce na HL. Amwe mu mabara n'amamodeli ya valves ashobora kutashobora gukorwamo valves zikingira uduce.)

6. Isuku, niba hari ibindi bisabwa kugira ngo habeho isuku y'imbere mu muyoboro w'amazi. Ni byiza ko abakiriya bahitamo imiyoboro ya BA cyangwa EP nk'imiyoboro ya VIP imbere kugira ngo bagabanye kwangirika kw'ibyuma byayo.

7. Akayunguruzo k'ubushyuhe bw'imvange: Sukura imyanda n'ibisigazwa by'urubura mu kigega.

8. Nyuma y'iminsi mike cyangwa myinshi ifunzwe cyangwa ibungabungwa, ni ngombwa cyane gukonjesha ibikoresho bya VI Piping na terminal mbere yuko amazi ashyushye yinjira, kugira ngo hirindwe ko amazi ashyushye yinjira mu bikoresho bya VI Piping na terminal. Imikorere yo gukonjesha igomba kwitabwaho mu miterere yayo. Itanga uburinzi bwiza ku bikoresho bya VI Piping n'ibikoresho bishyigikira imiyoboro nka valve.

9. Ikoreshwa muri sisitemu y'imiyoboro ikoresha amashanyarazi (flexible) ndetse n'ikoresha amashanyarazi adahindagurika.

10. Sisitemu yo gufunga imiyoboro ya Vyumba Ifite Ubushyuhe Bukomeye (Ishobora Guhinduka): Igizwe n'imiyoboro ya VI Flexible na/cyangwa imiyoboro ya VI, imiyoboro ya Jumper, Sisitemu yo gufunga imiyoboro ya Vyumba Ifite Ubushyuhe Bukomeye, Ibice Bitandukanya na Sisitemu yo gufunga imiyoboro ya Dynamic Vacuum (harimo imashini zifunga imiyoboro ya Vyumba, imashini za solenoid na gauges za vacuum nibindi). Uburebure bw'umuyoboro umwe wa VI Flexible bushobora guhindurwa hakurikijwe ibyo umukoresha akeneye.

11. Ubwoko butandukanye bwo guhuza: Ubwoko bwa Vacuum Bayonet Connection (VBC) na Welded Connection birashobora gutoranywa. Ubwoko bwa VBC ntibukenera ubwikorezi bushyirwa ahantu.